WMS Questionnaire

Which Functional Aspects Does the WMS Questionnaire Cover?

The questionnaire for Warehouse Management Systems (WMS questionnaire) is part of the system questionnaires, which together form the basis of the »Logistics IT Database« provided by Fraunhofer IML.

The questionnaire for Warehouse Management Systems (WMS questionnaire) is part of the system questionnaires, which together form the basis of the »Logistics IT Database« provided by Fraunhofer IML.

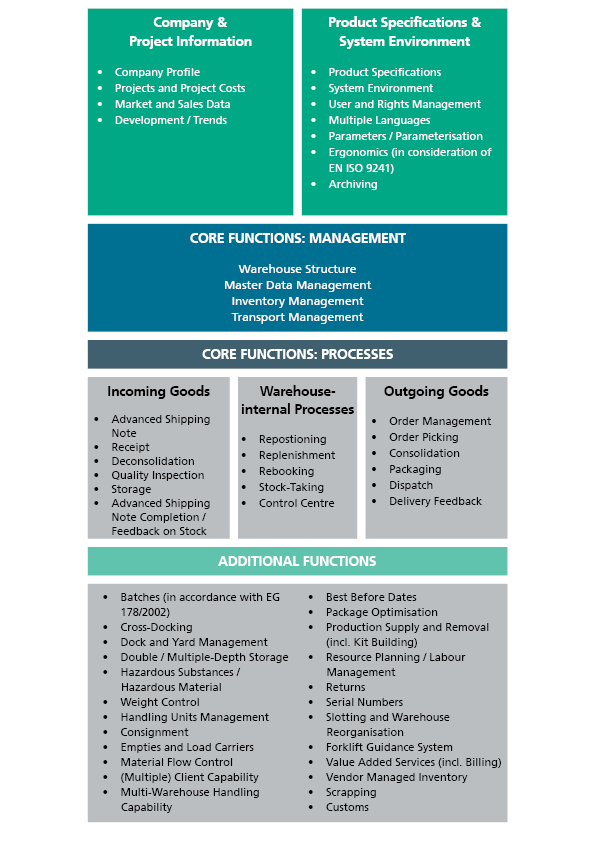

In addition to general aspects about the company, the WMS questionnaire also covers the company’s range of services and experiences. The focus of the questionnaire is on the functional support of the typical functions and processes in a warehouse. The questionnaire captures the core functionality – required for every warehouse – as well as the flows for material and information from receiving to shipping. Additional functionality that is required because of the different branches, product ranges, or desired degree of automation of a warehouse is indispensable to the successful operation of a warehouse.

The result of the questionnaire is a level of detail that defines the individual requirements of the user as well as the functional ability of the WMS solution. Typical questions are

- Based on which criteria does the system decide on the necessary of a quality test?

- Is it possible to manage the layout with the content of a handling unit?

- With which method does the package optimization and the charge carrier optimization take place?

The questionnaire is divided into functional areas that correspond to the functional structure of a WMS. The structure is orientated on the standard VDI 3601: warehouse management systems, which is developed in cooperation with the WMS Advisory Committee.

Scope of functions of the WMS Questionnaire

The questionnaire also captures other information about the developments, trends, and evaluations of each company in the WMS market. This data is incorporated into the regularly updated WMS Market Report Compact.

The questionnaire is modified and/or expanded each year to accommodate the latest requirements and developments. Project experience and the feedback from the users of the database (WMS providers, WMS users, and consulting companies) are used to make these changes.

Validation and Use of the Data

The data provided by a Logistics IT provider is not added to the Database or made available for use by »Logistics IT Online Selection« until it has been successfully validated. The annual updating of the questionnaire combined with the yearly validation of the data is what guarantees that the data is always up to date.