Definition WMS / IMS

What is a WMS, What Is an IMS Respectively?

The definition frequently causes some difficulty: Is an Inventory Management System (IMS) the same as a Warehouse Management System (WMS)? Is WMS not just the English equivalent of the German IMS? What is the difference between an IMS and a WMS?

The following definitions explain the differences between the two.

Notice: Since September 2015, the final version of the standard VDI 3601 is available in the Beuth publishing house. The present standard describes task and performance areas that define an IT system as a warehouse management system (WMS).

Inventory Management System vs. Warehouse Management System

An Inventory Management System is primarily a system for managing quantities and locations (bins) and their relationships to each other. Additional functionality could include the management of the transportation systems. An Inventory Management System can also be viewed as a stock management system.

In general terms, warehouse management refers to the monitoring, control, and optimization of complex warehouse and distribution systems. In addition to the basic functions of warehouse management, such as quantity and bin management and transport management and scheduling, Warehouse Management Systems also include numerous methods and means for controlling the system states and a selection of operating and optimization strategies. The main tasks of a WMS are to manage and optimize the internal warehouse systems.

In practice, the terms Inventory Management System and Warehouse Management System are often used synonymously.

Want to learn more? We recommend that you read the WMS MARKET REPORT COMPACT.

The Functionality of a WMS

The majority of WMS users want a customized version of a standard WMS, which means that the standard WMS provides all of the functionality they need for their specific business process without them having to pay for a (costly) custom solution. The providers have to respond to this demand by developing a modular system that allows the customer to select the settings and functionality that they need.

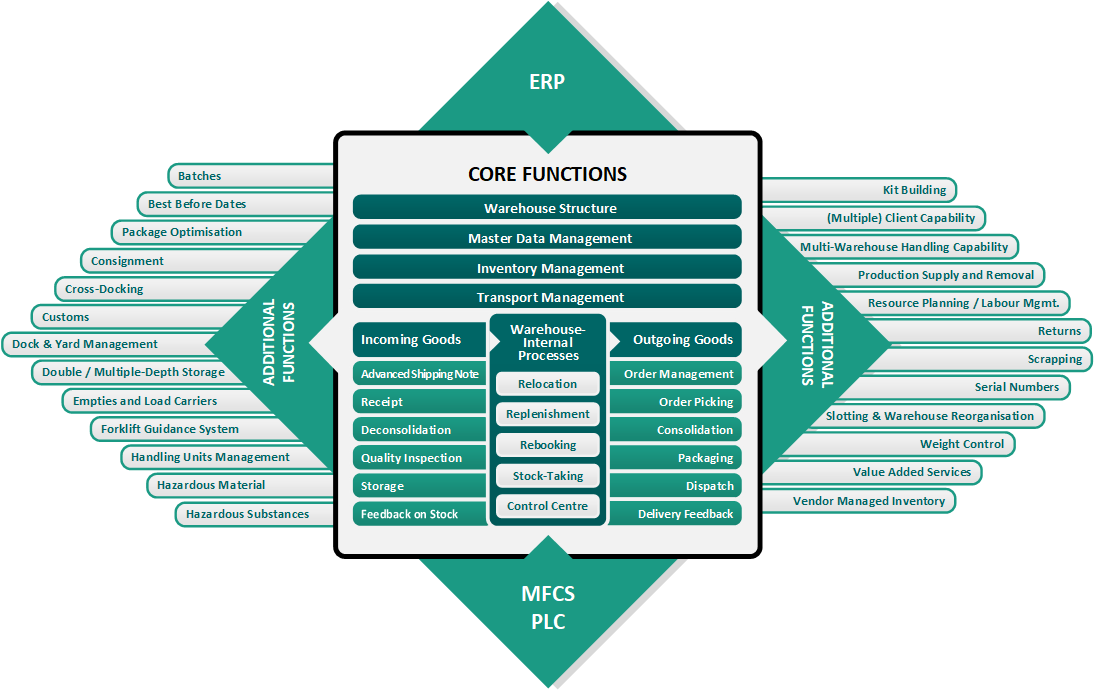

A modern WMS had a modular structure in which the individual functionality is divided into three groups: core functionality, additional functionality and expansion modules. This allows the customer to install only the modules that they require instead of the entire WMS. If the customer needs to expand the functionality of their system in the future to support new tasks, they can simply add the required modules to their existing system and activate them: according to the information provided by the providers this should work seamlessly. The customer usually only has to pay for the required functionality.

A standard WMS has all of the functionality required for managing and optimizing the internal warehouse systems. Fraunhofer IML considers all of the functionality required from receiving to shipping to be part of the core functionality of a WMS.

In essence, the user defines the scope of a WMS. Any functionality that the user considers to be necessary belongs to their WMS.

Core Functionality

The core functionality is part of the common functionality of a WMS. It is necessary for the operation of the WMS and it is part of the minimum installation of each system. A company that specializes in that area could offer some other core functionality, such as inventory, as a separate module. Normally, the core functionality for a WMS is only available in modules provided by the WMS provider. The core functionality supports the main area of application of a WMS: from receiving to shipping.

Additional Functionality

Usually some additional functionality is also part of the common functionality of a WMS but it is only installed if the customer requires that specific functionality. The additional functionality can also include modules that are offered separately by specialists, such as dock and yard management and resource planning. They will be connected to the WMS via an interface. Additional functionality is usually part of the standard product line offered by a WMS provider.

Expansion Modules

xpansion modules, such as RFID software or Pick by Voice, are usually separate software packages that expand the functionality of a WMS or optimize the processes within a warehouse. They are not usually developed or sold by a WMS provider with the exception of Pick to Light systems and, very rarely Pick by Voice systems. The expansion modules are developed for all types of WMS and can be connected to any almost any WMS.